Pool Equipment Piping

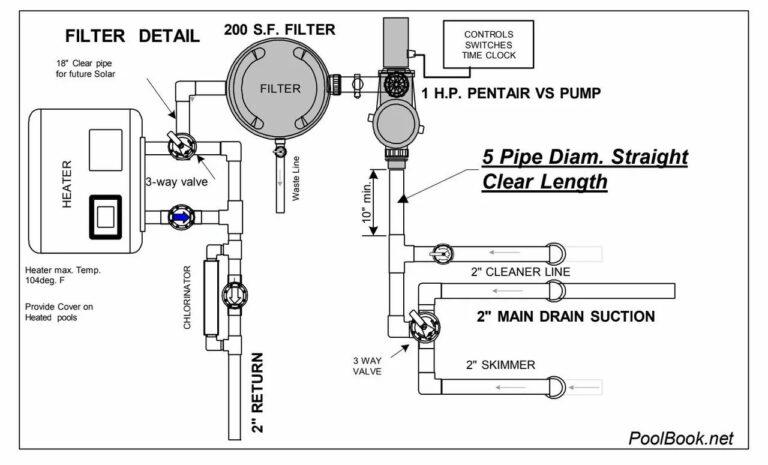

Pool equipment usually consists of the following components and they should be installed in this order. Pump – Filter – Heater – Chlorinator

If a second heater is added the piping will be heat pump then gas heater then pool return. The chlorinator is always the last component in the flow path.

Heaters and chlorinators require a minimum flow rate to operate, (flow switch) Variable speed pumps may need to be set to the rpm or speed required to meet the min flow rate for these components to operate.

If pump performance is not up to par or if bubbles are visible in the pump strainer housing it is usually caused by the failure to provide a minimum clear straight length of pipe on the pump suction side. Example: 2″ pvc pipe would require a minimum length of 10 inches.

All new pools should have variable speed or two speed pump.

All remodeled pools should be upgraded to a variable speed or a two speed pump.

Avoid increasing pump size (h.p.) unless you also address pvc pipe and other component size for the increased flow rate.

The components of a pool are engineered to be compatable for safety, energy efficiency,pump life and performance. This includes all piping, filter, main drains and any other components in the flow path. Example: Do not add a 3 h.p. pump to a system with 2″ piping and 1 main drain and a small filter. Add a second main drain (in the wall if necessary), a larger filter and increase pipe size.

Provide matching components (by manufacturer) whenever possible for better warranty.

A typical swimming pool piping installation will follow this criteria.

The steel installer will place the main drain and pressure test the pvc lines prior to gunite.

He will also place all other components, lights, vac. lines , return lines, skimmers and features

necessary prior to gunite. After gunite the pool will be backfilled and a new trench will be dug (min.

18″ deep) to allow the pool perimeter piping to rest on a clean sand base free from rocks and

debris around the pool and to the equipment. After a successful pressure test the piping will be

backfilled with clean fill free from rocks and debris.

The pool piping will include the vacuum line

installed mid pool 12″ to 18″ down from pool waterline and equipped with a spring loaded cover.

The skimmer will be located to take advantage of the prevailing winds in the area. One skimmer is

usually adequate up to 500 square feet of pool surface.

The return lines, (usually three), are located (min. 12″ down) to provide a counter clockwise flow of return water to the pool.

The main drain is located pool bottom at the deepest point and its primary function is not to drain the pool. The main drain is essential to thorough circulation of the pool , (water, chemicals, and heat,) and keeps the pool bottom clean. Three and sometimes four returns (strategically located) are always sufficient and adding more will diminish the flow and power of each return.

Floor returns, (fittings) are sometimes added to provide circulation on sun shelfs and other areas.

Bubbler fountains and other features also aid in circulation. Pools with water features and

waterfalls are often equipped with auto fill or auto level devices as they have a much higher loss

due to splash and evaporation. An overflow line is sometimes added to maintain the waterline at the correct level for skimmer operation. A skimmer will not work in an overfilled pool.

Skimmers are not installed in negative edge and perimeter overflow pools.

Pool equipment should be installed at deck level. If the pump is installed above deck level it will not prime and will have a short life. If can be installed below deck level but all lines must be valved for service and maintenance operations.

PIPING: ALL POOL PIPING SHALL BEAR THE N.S.F.-PW SEAL OF APPROVAL AND

SHALL BE SCHEDULE 40 P.V.C. MIN.